Unitized Curtain Wall

UNITIZED is a Glass - Aluminum Frame product - CURTAIN WALL. UNITIZED products are very distinguished of the industry, specificly used to carry out the glass wall items surrounding the Buildings, offices or Center Malls. Recently in Vietnam, many condominiums required architectural features as well as wide views have been applying diferent façade systems.

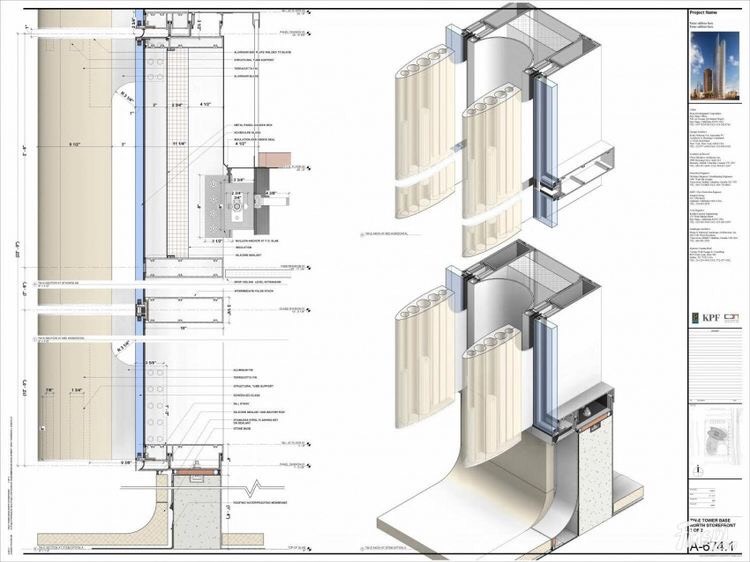

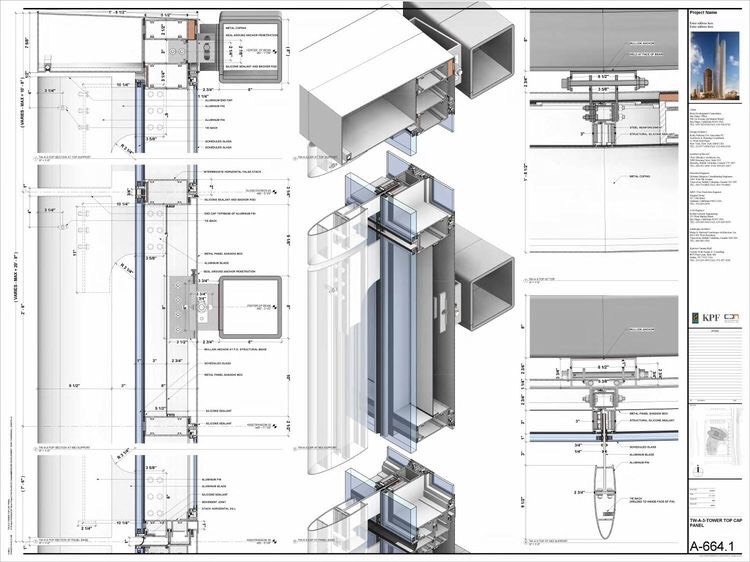

Different from other products, Unitized curtainwall systems are engineered to be fully assembled and glazed in the factory known as PANELS then delivered to the project site. The PANEL are installed through the bracket system, anchored into the main frame of the building. Therefore, UNITIZED is highly homogeneous and has a solid, seamless connection, especially with current technology, the system can perform earthquake resistance and has a sufficient shift wide to protect against earthquake shaking.

HASKY is proud to be one of the most qualified and prestigious units in designing, manufacturing and executing UNITIZED wall system in Vietnam. HASKY has experienced executing many UNITIZED projects in Vietnam such as: Phu Quoc Airport, Tan Son Nhat Airport, Da Nang Airport, Cam Ranh Airport, Sunshine City, etc.

Benefits of Unitized Curtainwall:

- Large and unified surface adapt to modern design concepts

- Easy construction, fast construction time to meet the requirements of projects

- Factory assembled, providing enhanced quality control

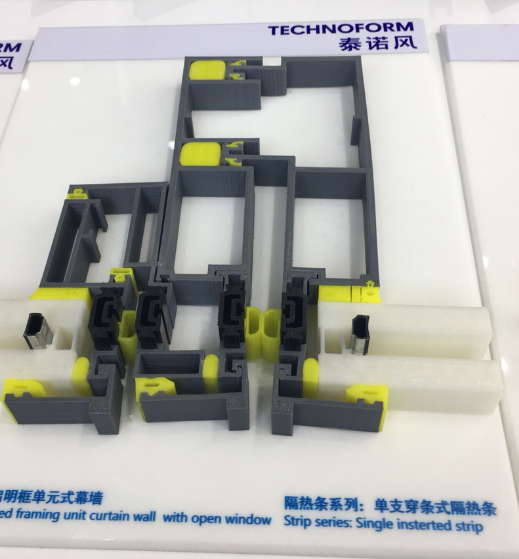

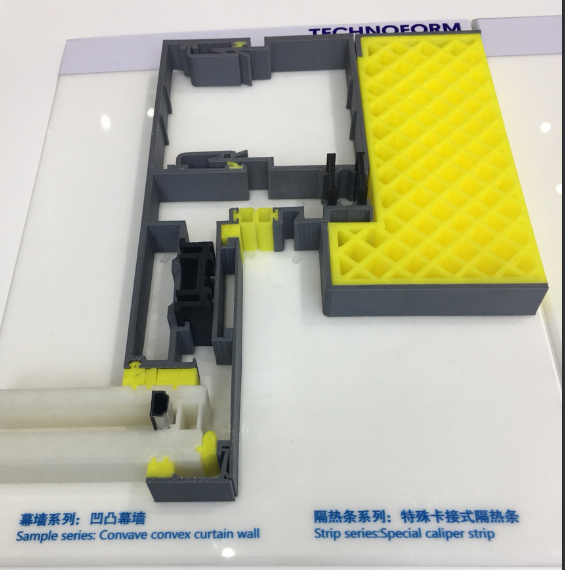

- High performance systems (thermal, air, water, dynamics)

- Do not occupy much space for installing and store at the construction site.

- Accommodation of multiple spandrel systems (glass, metal panels, stone, terra cotta, etc.)

Disadvantages:

- Requires continuous and sequential construction. Only good applying on facades with less angular and large curvature.

- Time-comsuming process at the factory, and requiring high precision and flexible machines (CNC)

- Unitized façade system does not suitable for constructing multi-angled buildings, and curvature with small radius. => leading to higher expense on desining and producing specific

- Profile for each location.

- Transporting panels is more complex, requires higher cost.

- Higher requirements for inspection, designing and manufaturing.